From Buffer With Love

Alleged Mouldy Malpractice; Multiple Manufacturers

Credit: Brook Jackson for the lead, and Jikkyleaks for enduring our rambling.

The Daily Beagle previously had gotten wind of a Tweet showing images that appeared to depict mould on equipment found at a Pfizer and Moderna associated manufacturing plant, which we planned to cover in “DNA Modifications Impact The Next Generation”, however the Tweet had disappeared.

We spoke with the Tweet’s author, famous whistleblower Brook Jackson, to find out what had happened. Brook has previously exposed clinical research firm Ventavia, a firm working on behalf of Pfizer, for corruption.

Brook revealed the Tweet images were from another lawsuit, one being brought by another whistleblower, David Stonebrook, under Case ID ‘1:21-cv-10866-DJC’, or to give the full name:

United States of America, ex rel. David Stonebrooke v Merck KGaA, Darmstadt, Germany; Sigma-Aldrich Corp; EMD Millipore; Research Organics LLC

Quite a mouthful.

The Tweet was deleted as it required clarification due to complexities of the case — difficult to sum up accurately in a single Tweet. Brook asked The Daily Beagle if we’d cover it. We said yes.

As for why there are so many companies named and how Pfizer and Moderna are involved takes some explaining.

Twisty Twists

Research Organics LLC were the former owners of the Cleveland property the lawsuit focuses on.

They were acquired by Sigma-Aldrich back in 2012, with Research Organics LLC placed under SAFC (Sigma-Aldrich Fine Chemicals).

Merck then entered into an agreement to acquire Sigma-Aldrich Corp back in 2014. EMD Millipore were already part of Merck and got integrated into Sigma-Aldrich during the acquisitional merger, which formed MilliporeSigma, also under Merck.

For the US and Canada, they’re known as ‘MilliporeSigma’ (still under Merck), but for the rest of the world, it is simply known as Merck.

Hitting The Buffers

The SAFC Cleveland site manufactures materials including Tris (Tris(hydroxymethyl)aminomethane) and HEPES (4-(2-hydroxyethyl)-1-piperazineethanesulfonic acid). The lawsuit alleges that the orders of Tris and HEPES were sent to Pfizer and Moderna:

The lawsuit also alleges screenshots from what appears to be a spreadsheet showing what they allege are orders of TRIS UP and TRIS HCI going to Pfizer Inc:

Both Tris and HEPES are buffer solutions. Buffer solutions are meant to help stabilise the pH of a medical product (basically, how acidic or alkaline).

The pH of both buffers varies by temperature. This might raise eyebrows as the Pfizer shot went from frozen ‘ultra-cold’ (approx. -94F or -70C), to frozen ‘cold’ (approx. -13F to 5F; -25C to -15C), to ‘warmer temperatures’ (approx. 35F to 46F; 2C to 8C).

Why would pH matter?

The Pfizer and Moderna shots use LNPs (lipid nanoparticles). Pfizer uses ALC-0159 and ALC-0315 (ALC likely means ‘aminolipid cationic’) as part of mRNA delivery.

LNPs are changed by pH, changing the charge (positive, negative or net-neutral). At low pH, the LNPs become positively charged; at high pH, negatively, and at base pH (similar to blood), net-neutral. LNPs carry the mRNA, and are supposedly meant to ‘stabilise’ it (even though evidence shows the mRNA is unstable, so obviously not).

The charge of the LNPs dictate where they might end up in the body, and what they do. As a result, Pfizer and Moderna require a buffer solution to keep the pH controlled.

In theory.

In Alleged Practice

Alleged, as, of course, the lawsuit is pending and has not yet been concluded one way or the other, relating to mould (American: mold).

The alleged lawsuit does include photographs purportedly from the SAFC Cleveland site, depicting what is apparently an air filtration unit rife with what is alleged to be mould (pages 17 to 23 of this document). If you’re eating food, best finish before you continue scrolling. The braver among you can click to enlarge.

As you’re guessing, air filter units are not supposed to contain mould, allegedly or otherwise. As far as mould contamination comparisons go, The Daily Beagle couldn’t find a mould comparison worse enough to match for contrast.

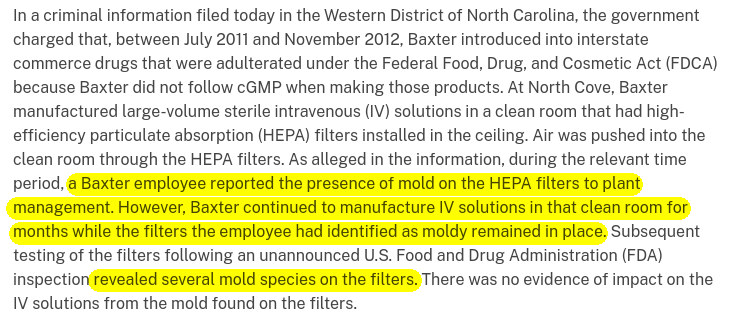

The complainant in the lawsuit however offers the worse example from another case they could find (on page 31), from an $18 million settlement to the Department of Justice by Baxter Healthcare Corporation for mold contamination:

Mould in a manufacturing process is obviously not GMP (Good Manufacturing Practice) compliant, and would constitute a Federal offence if true.

SAFC Cleveland Sorta Admit They’re Not GMP Certified

The Daily Beagle opted to try to investigate the allegations, and came across two “Site Quality Self-Assessment” documents for the Cleveland site. One dated 30th April 2021, and the other 26th September 2023.

The first page amusingly states they manufacture “high purity Biochemicals”. In the April dated Self-Assessment on page 5, it specifies clearly they they’re not registered — including the line “GMP certification”:

The September dated Self-Assement goes a step further in the contradiction games. On page 4 it claims it is part of the IPEC GMP (IPEC stands for International Pharmaceutical Excipients Council; they’re a European based organisation):

IPEC describe themselves as having stakeholders that including regulatory authorities:

Yet on page 5, it is clearly marked the SAFC Cleveland site is still not GMP certified:

Que? How does one export a product that requires GMP without a GMP certification?

Also curiously, one change between the Self-Assessment reports is whether or not they have a declaration of ‘Elemental Impurities’. In April 2021, on page 9, they mark it as ‘no’:

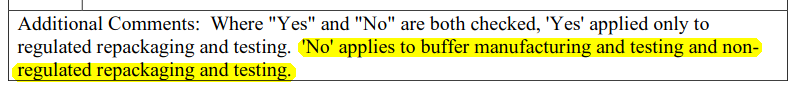

Odd for a ‘high purity’ site not to have that. In September 2023 on page 9, they updated their answer to… yes and no:

You’re probably confused, rightly so. The September report has a comment on page 10, where they clarify it is product specific. The absence for the Elemental Impurities is for the buffer manufacturing:

Huh. Weird, a “high purity” manufacturer doesn’t list impurities in a buffer solution.

Watery Staging Ground

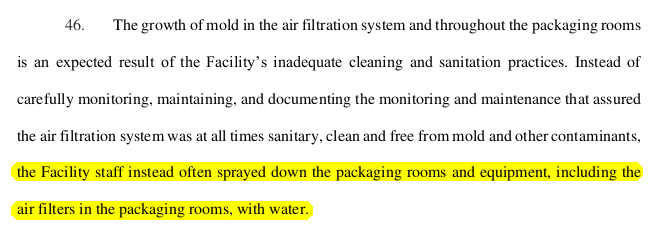

Returning to the photos, the interior of the air filter appears to be metal, although there might be paint that could possibly have a cellulose base. Mould typically requires materials with high cellulose (read: plant-based) material in order to grow, however it can also grow in the presence of persistent humidity (>70-80%), even on metal.

The lawsuit complaint alleges that SAFC Cleveland engaged in water spraying — which does not appear to be a standard cleaning practice — accounting for the high humidity:

The complaint alleges the water sprayings were so bad, they stained windows, with the lawsuit including the below image of what appears to be a water streaked window:

One would almost suggest the humidity was intentional, given the complaint alleges warnings of mould were disregarded (pages 28 to 30).

What do the Cleveland site Self-Assessment reports say? Well, they admit in the April 2021 dated paper on page 7 that “Validated Equipment Cleaning Procedures” … aren’t:

Maybe they fixed it after the complaint? Well, looking at the Self-Assessment report dated for September 2023, on page 7, it once again says “no” to “Validated Equipment Cleaning Procedures”:

You’d think with threat of lawsuit that they might have opted to use a Validated Equipment Cleaning Procedure.

What Type Of Mould Is It?

Given no sampling of the alleged mould has been done, the specific mould species isn’t currently known, but possibilities include: Stachybotrys Chartarum, Aspergillus Nidulans, and Aspergillus Niger. They’re all types of black mould. There could be others.

As a curious side-note, in unrelated research, Aspergillus Nidulans has been experimented on with recombinant plasmids, as well as enzyme and protein research, plasmids are also used on Aspergillus Niger for protein production research.

Stachybotrys Chartarum is a common black mould, some strains of which produce mycotoxins (making it a toxigenic fungi).

More astute minds might recall a period when Pfizer were trying to hype up the connection between black mould (a fungus) and COVID-19, in an undated article that appeared in early 2022, trying to suggest this rampant outbreak of black fungus was about to occur.

The COVID-19 and black fungus was ultimately a non-event, and contrary to Pfizer’s scaremongering, did not spread worldwide.

Bizarre then that Pfizer would dedicate an entire page trying to blame COVID-19 for black fungus infections — post-shot rollout, no less. They claimed it was “Aspergillus fungi” (a general term for all Aspergillus mould), but failed to elaborate which species.

Central Airways

The complaint alleges the above air filter’s ductwork (airflow) leads to the packaging room on page 17.

Page 22 also alleges that:

[…] ductwork leading to packaging Room D, where TRIS and HEPES were packaged […]

This means Tris and HEPES buffer solution provided to Pfizer and Moderna could also be contaminated with mould.

It is unclear what effect mould would have on a buffer solution, but possibilities range from: altering pH of the final solution, introducing mycotoxins, resulting in mould being injected into people’s bodies as part of the Pfizer and Moderna shots, besides other as of yet unknown risks.

Mysterious Trend

Before anyone leaps to the ‘incompetence’ defence (we say: don’t attribute to incompetence what is malice), there were two other instances of mould in relation to the poison shots.

The first is Pfizer’s Kansas facility:

And the second, which The Daily Beagle has mentioned previously, is the Emergent facility who produced shots for AstraZeneca and Johnson & Johnson, which also had mould, resulting in 400 million doses being destroyed:

Emergent similarly had poor disinfection procedures and had been warned multiple times:

What is it with these shots and mould?

In Summary

Lawsuit alleges mould contamination at SAFC Cleveland site that reportedly provides buffer material to Pfizer and Moderna. Lawsuit provided photographs of a horrifying scene, and allege contaminated ductwork is connected to buffer Tris and HEPES packaging room.

SAFC Cleveland have self-assessment reports that do not paint their cleaning procedures in a good light. Both report that site does not have GMP certification, nor is Elemental Impurities checked in buffer solutions.

Buffer is used by Pfizer and Moderna to stabilise pH, which impacts LNPs (lipidnanoparticles), whose charge, and thus behaviour, changes depending on pH.

Tris and HEPES' pH changes depending on temperature, and Pfizer have changed the temperatures of their shots from frozen to below room temperature, likely impacting pH in the process.

Black mould could possibly be Stachybotrys Chartarum, Aspergillus Nidulans, and Aspergillus Niger. Plasmids and protein research is conducted on Aspergillus Nidulans and Aspergillus Niger. The actual mould species is unknown.

Pfizer previously published a press release in 2022 fearmongering COVID-19 and black fungus, which they vaguely suggested was a "Aspergillus fungi" without clarifying species. The reports only occurred post-shot rollout.

This isn't the first time mould contamination has been reported at sites involved in shot manufacturing; the Pfizer Kansas facility and the Emergent (AstraZeneca;Johnson&Johnson) facilities also had mould.Related Articles To Read

Found this informative? Receive more for free!

Raise awareness?

What do you think, dear reader? Let us know in the comments.

This is a brilliant piece bringing the lawsuits together in the context of the serious nature of this mould contamination. Well done

A picture worth a thousand words